This post was originally published on July 16, 2021. It was updated to reflect current developments and republished on March 6, 2023 and then again on September 23, 2025.

Probably the greatest concern (or complaint) our customers have about our products is their plastic packaging. We do have some excellent non-plastic options for our customers—including our Bar Soaps and Organic Magic Balms—but the majority of our products are currently packaged in plastic.

We share our customers’ concern and know we have work to do to make our packaging more sustainable. So we are actively pursuing a multi-pronged approach to minimize the ecological and social impacts of our packaging, support circularity and reuse, and hopefully ultimately find alternatives to plastic.

Unfortunately, moving away from plastic packaging is not fast or simple—if a packaging solution existed that could effectively deliver our products to our consumers around the world and we had certainty that it was a more ecological option, we would switch right away. But there is no magic bullet, so for the time being, we have to pursue multiple strategies to first minimize and then mitigate our impact, while we work to develop better options. Read on to find out everything we’re doing to address the issue!

Table of Contents

- Post-Consumer Recycled and Recyclable Plastic: Considering Both the Alpha and the Omega

- But It’s Still Plastic!

- Reducing: Less Plastic through Refill Cartons

- Reusing and Refilling: Pilots on the Path to Circularity

- World’s First Circular Dr. Bronner’s Refill Station!

- Exploring Plastic Neutrality and Reducing Global Plastic Pollution

- Changing the Infrastructure for Recycling and Composting

Post-Consumer Recycled and Recyclable Plastic: Considering Both the Alpha and the Omega

We consider plastic both in terms of upstream impacts—the origin of the material, and downstream impacts—the end of life for the material.

All of our plastic bottles are now made from post-consumer recycled (PCR) plastic, a practice Dr. Bronner’s helped pioneer more than fifteen years ago—in fact, we were the first American company to package liquid soaps in 100% PCR plastic bottles. Even today, most companies using plastic packaging don’t use PCR plastic, let alone 100% PCR. The unfortunate reality is that according to the EPA even the most recyclable PET containers are likely recycled in the U.S. at a 29% rate at best, and a recent Greenpeace report that total plastic recycling in the U.S. has actually dropped to less than 6%. In fact, according to the Ellen McArthur Foundation, only ~2% of the world’s plastic each year gets actually recycled into new plastic products. But we are committed to using PCR plastic as long as we use plastic, since we believe PCR plastic is a huge improvement over virgin plastic, even plant-based virgin plastic. PCR plastic takes less energy to produce than virgin material and more importantly avoids putting new plastic out into the world. Making PCR plastic products also builds market demand for recycled plastic, which helps make plastic collection and recycling more economically viable around the world.

We aim to get as much of our plastic packaging from post-consumer recycled sources as possible. In 2024 we were proud that 84% of all of our plastic packaging was from PCR material. In 2022 we also successfully switched our gallons and half gallon bottles from virgin to PCR plastic, meaning that now all of Dr. Bronner’s plastic bottles are 100% PCR plastic. We also increased the PCR material in the plastic resin used to make some of our 16 oz., 25 oz., and 32 oz. bottle caps, and are proud that many of those caps now contain 80% PCR material.. While we celebrate these successes, it continues to be a challenge to find PCR plastic options for all packaging bits and pieces—like labels and sprayers—but we’re working on those too.

In terms of end of life, we know we cannot recycle our way out of the plastic pollution problem our planet faces, compostable packaging is a challenge since compost requires mostly food scraps for nutrients, we dream of a day when all packaging can be reused. In the meantime, we think it’s important and practical to ensure that our packaging is as recyclable as possible. For recycling, the type of plastic matters, as well as the size, color, and even sometimes the shape. Recycling facilities, particularly those in the U.S., often rely on automated sorters and sensors to identify recyclable materials and funnel them into the correct recycling stream. In practice, this means that many plastics which should be recyclable are not correctly identified, and end up in landfill instead of being recycled.

For example, most recycling facilities have grates to sort out smaller items. If a plastic item is small enough to fall through the grates, it ends up in landfill, even if it is “technically” recyclable. For this reason, we will be phasing out our 2 oz. bottles of Pure-Castile Soap in our domestic markets, and replacing them with a 3.4 oz. size that is more likely to be correctly sorted as recyclable, while still being travel-friendly & TSA-approved.

Aside from smaller plastics, darker-colored plastics are often rejected by sorting machines and not recycled. This is because it is difficult to turn darker plastics into lighter colored pellets that can then be used to make new products with customized colors; there is less of an end market, so less incentive for recyclers to take the time to separate the material. That’s why we’re also working on replacing some of our darker plastics with more recyclable options.

And sometimes the bits and pieces of a package – like the cap or the label – can determine whether an item is properly sorted or not. For example, a colored label may cause a clear bottle to be incorrectly identified because the sensor recognizes the color or material of the label instead of the color or material of the bottle itself. To address this challenge, in February 2025 we reduced the size of our labels. This change will not only increase the chances of our bottles getting recycled, but will also result in less total plastic being used since our labels are made from plastic. We expect the label material reduction to reduce over 33,000 lbs of plastic per year.

But It’s Still Plastic!

At this point, you might be thinking, less plastic and lower impact plastic packaging is good and fine —but shouldn’t we be moving away from plastic altogether? The answer is a resounding yes, but figuring out how to do that, all while still providing quality and value to our customers, is not simple or straightforward.

When considering a material to replace plastic, we think about the entire lifecycle of the material. Many materials that appear at first glance to be more ecological turn out to be problematic when you look into them closely. Often the infrastructure and markets do not yet exist to support the full lifecycle of an alternative material, and it usually has hidden environmental and labor impacts to consider. We might identify a bio-based plastic that works for our products, but then must fully consider its agricultural impacts. Is the corn, sugar, or potato for the plastic grown with pesticides? Should that land be used for growing food or generating solar power instead? Another example is glass: at first glance it would seem to be a good alternative—but would probably be dangerous to have in the bathroom, and is so heavy that the greenhouse gas impacts for transporting it are significant compared to plastic, which is relatively light. Aluminum—with its “infinite recyclability”—seems promising, but has significant environmental and labor impacts when considering the mining and production of the virgin material, and we have struggled to find high-quality PCR aluminum sources.

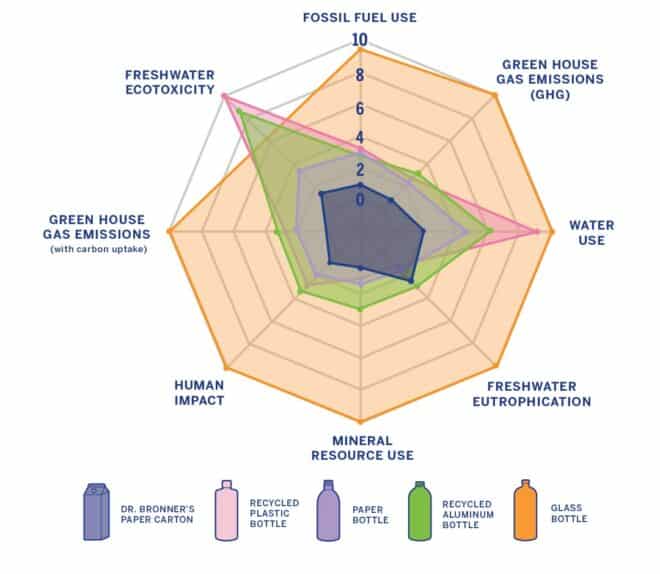

Reducing Plastic: Less Plastic through Refill Cartons

Despite the challenges, we are committed to innovating better packaging solutions. In 2021 we partnered with our friends at OSC to conduct a Life Cycle Analysis (LCA) screening on alternatives to our PCR PET bottle. We wanted to compare PCR PET to alternative materials for a single-use container, including glass and aluminum. What we learned was surprising: mostly-paper cartons, although not impact-free or even fully plastic-free, had the smallest environmental impact of all of the single-use packages evaluated, including when compared to our current PCR PET bottle. In addition to this Life Cycle Analysis, Dr. Bronner’s conducted a literature search of peer-reviewed published LCAs comparing cartons to alternative packaging options to further explore the relative impacts of a paper carton compared to other packaging systems. This additional research also supported the initial LCA results that cartons are the most sustainable single use option available today. So we launched cartons in the marketplace in the summer of 2023. The cartons are not completely plastic–free, they are 86% less plastic than the bottle of the same size, they may not be recyclable in all markets, and they are still considered a single-use package, but we are nevertheless proud to be moving in a more environmentally-friendly direction.

Reusing and Refilling: Pilots on the Path to Circularity

We’ve always encouraged customers to buy our soaps in bulk: buying or refilling a large container of soap and using that to fill smaller containers you have around the house is a great way to reduce single-use plastic use. We love it when retailers offer refill stations for our soaps. We sell a five-gallon container of soap to retailers, along with a special spigot, and shoppers can then refill their own bottles with soap at the store. To see if a store near you offers our soap in a bulk station, you can now visit our store locator and filter for bulk.

In many communities, once all the soap is sold from the store’s large containers, those empty containers are recycled or given away for creative reuse to store employees or community organizations. But in some places, the containers are too big to be processed at the local recycling facility. We do offer a free container mail-back program for our wholesale zero-waste shop customers and we are piloting reuse options. But there are many barriers for stores considering returning their empty containers to us: storage and staffing limitations, the design of contracts with distributors and freight companies, high shipping and mailing costs for bulky items that increase the farther away a store is from Southern California, the carbon emissions of shipping containers around, and simple wear and tear on containers. So in 2022 we began to explore different bulk container and distribution designs.

We were thrilled to connect with a Northern California-based start-up, Wonderfil, as they launched a circular refill service station at UC Santa Cruz. The mobile station holds reusable plastic cartridges of bulk liquid products underneath a countertop with friendly tap handles and a sleek digital interface for customers. Although not plastic-free and likely not recyclable, the cartridges are nevertheless designed for reuse and can be flattened and shipped more efficiently and cost-effectively than large, rigid containers. Once all the liquid soap inside is sold, the empty Dr. Bronner’s cartridges are flattened and shipped back to our factory to be refilled for Wonderfil’s next order: a refill system with lower return shipping costs, lower return transportation emissions, and no single-use plastic! After a successful first year, the station is doing well and Wonderfil is growing; Wonderfil has since launched at Pomona College & CSU Monterey Bay with plans to expand to other college campuses in the coming months. In 2024 we partnered with Wonderfil & Whole Foods Market to pilot refill stations at five San Francisco Bay Area stores, and a social media post showcasing the refill stations went viral. We hope this is just the beginning. And now we want to bring our learnings a little closer to home and into the retail environment.

World’s First Circular Dr. Bronner’s Refill Station!

Inspired by the keg refill and distribution model of the brewing industry, we partnered with Kombucha on Tap, a local company that distributes and services keg stations of organic kombucha and cold brew at locations across Southern California (including to our Dr. Bronner’s employee lounge!), and another local business, Jimbo’s Naturally, an award-winning independent organic grocery retailer, whose fearless leadership team was willing to trial bulk dispensing systems, pricing, in-store marketing campaigns, and empty container reverse logistics with us at their flagship store in Carmel Valley, San Diego. Together in late 2022 we launched the world’s first circular Dr. Bronner’s refill station at a grocery store! This was such a success that in Summer 2023 we added more refill stations at Jimbo’s three other San Diego County locations: Carlsbad, 4S, & Escondido, as well as at the Ocean Beach People’s Food Co.

We sell large drums of our soap to our distributor, who then fills smaller containers to sell to the stores. The distributor services the stores’ refill stations, swapping out the empty smaller containers with freshly refilled ones. When the distributor’s drums are emptied, they are returned to Dr. Bronner’s and refilled; repeating loops of durable containers moving liquid soap from factory to shopper.

A handful of stores, one distributor, one product type. But we are learning every day about ways to improve the program for customers, store employees, reverse logistics, and more. And this station has fueled the dream of a transformed shopping experience and the day when all liquid products can be distributed in a refill format. If all goes well, we hope to expand our circular refill program with other distributors, retailers, and brand partners all across the country and beyond.

Exploring Plastic Neutrality and Reducing Global Plastic Pollution

Implementing packaging improvements and innovating towards circularity takes time, and meanwhile we continue to sell products in plastic packaging. We want to take responsibility for this ‘plastic footprint’ even as we work to shrink it.

Another strategy we are employing to reduce the impact of our plastic packaging is what is sometimes called “offsetting,” or in our case, “insetting.” You may be familiar with the concept of offsetting from the world of greenhouse gas emissions. Companies that emit greenhouses gasses can offset their emissions by buying credits to sequester an equal amount of carbon—for example, if they pay to plant trees that sequester an amount of carbon equal to what they emit through non-renewable electricity use. This means that they are effectively “carbon neutral”—even though they put carbon into the atmosphere, they are making sure that an equal amount of carbon is taken out of the atmosphere. “Insetting” is essentially the same concept as offsetting, but when the financial investments and environmental activities take place within a company’s own supply chain.

A similar concept to carbon offsets can be applied to plastic, allowing companies to pursue “plastic neutrality” by paying to recover plastic from the environment. This is a fairly new concept, and therefore the credits are sold in relatively new markets compared to carbon credits. In our case, we want to collect—and then recycle or reuse in some way—not only the same amount of plastic that we produce through our packaging, but also the same types of plastic that we produce, since we know not all plastic is equally recyclable. And, we want to invest in our own supply chain communities, as we have done with fair trade projects and regenerative organic agricultural efforts around the world that “inset” some of the carbon footprint of our soap production and support the communities where our raw materials come from.

In 2022 we began a pilot collecting plastic waste from the streets, lands, and waterways in Asuom, Ghana, the community where our Bar Soap’s palm oil is produced. Like so many communities around the world, Asuom lacks municipal infrastructure for collecting plastic waste, so plastic often either ends up polluting the local environment or being burned in piles which can create harmful air pollution. Our plastic insetting pilot aims to collect this waste as part of our supplier Serendipalm’s fair trade business operations, creating new fair trade jobs and allowing the material to then be recycled or downcycled locally (perhaps into asphalt or other durable products), while the trash littering the communities is cleaned up too. If the pilot goes well, we hope to build out this program in other fair trade supplier communities and ultimately ‘inset’ our entire plastic footprint over time. We don’t see insetting as a reason not to innovate out of single-use plastic and reduce our footprint, but rather as a critical opportunity to address our existing impact and fight plastic pollution even as we work to reduce that impact and do our part to address the plastic pollution problem over time.

Changing the Infrastructure for Recycling and Composting

As described above, it is not enough to produce technically recyclable or compostable single-use packaging. If the infrastructure and economic markets don’t exist to sustainably support its end-of-life path, that packaging will most likely end up in landfill or simply leaked into the environment, polluting our lands, oceans, rivers, and communities. That’s why Dr. Bronner’s supports “extended producer responsibility” policies that will create additional recycling and composting infrastructure both in our home state of California and in the U.S. as a whole.

In California, we supported SB343 and SB54 and were major donors (through New Approach PAC) to the California Plastic Waste Reduction Regulations Initiative, which qualified for the California State ballot for public vote in November of 2022. The ballot measure informed SB54 which was then signed into law in 2022. We hope that in the rule-making process SB54 will be developed into landmark legislation that can set precedent for other policies across the country and hold companies, ourselves included, accountable for the packaging we produce, support environmental remediation and environmental justice efforts, and develop better recycling and composting infrastructure.

On the federal level, we support the Break Free From Plastic Pollution Act (H.R. 5845). This bill would make packaging producers fiscally responsible for collecting and managing the recycling or composting of the packaging they create (after consumer use). It would also increase the minimum of recycled content that must be contained in packaging, and phase out the use of certain products, such as plastic utensils. We also support updating the FTC’s Green Guide to include more accurate information about what is truly recyclable.

At the local level, we are advocating to ban single-use plastics and invest in better composting facilities in the beach communities around San Diego County, including the City of Vista where we are located.

But there is more to be done. And we know we cannot do it alone.

We have partnered together with other companies to share pre-competitive best practices, leads, and collaborate on projects, including advocacy. We are proud to be members of the following working groups, and are excited to learn from other companies and work together to innovate and advance solutions:

- OSC’s Packaging Collaborative & the RCD Redefining Flexible Films Innovation Workshop:

- Grove Collaborative’s Beyond Plastic Working Group

- prAna’s Responsible Packaging Movement

And we need your help as consumers and partners. Please join us and get involved with Plastic Free July to see how you can minimize plastic in your own life and be part of the solution!