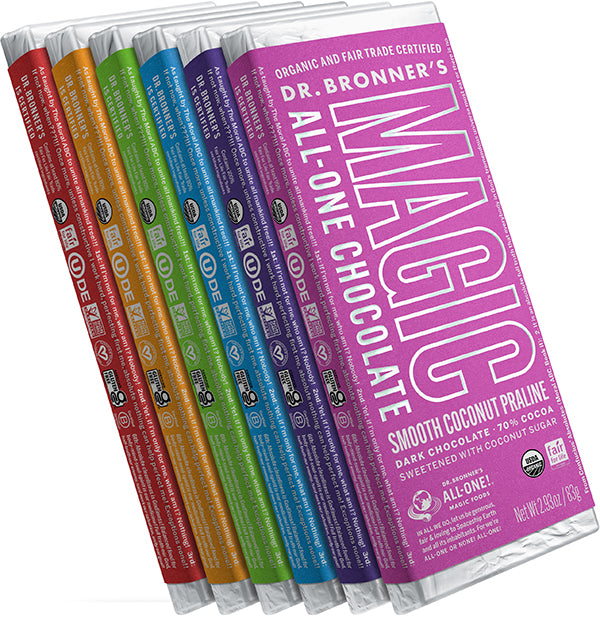

Have you ever wondered where chocolate comes from? How Dr. Bronner’s yummy Magic All-One Chocolate is made?

Rich, dark, wonderfully delicious chocolate, with its magical, mystical tastes and alchemical effects?

Well, lets start by sharing a few chocolate making secrets with you…

Table of Contents

- History and Significance of the Cocoa Plant

- The Importance of Sustainably Grown High-Quality Cocoa

- What Is the Cocoa Harvesting Process Like?

- Using Coconut Sugar Instead of Cane Sugar

- What's the Process of Making the Chocolate?

History and Significance of the Cocoa Plant

The cocoa plant was given the scientific name Theobroma Cacao by Linnaeus—Theobromameans “food of the gods” in Greek, and Cacao derives from the Mayan and Nahuatl words for cocoa. Some research suggests that eating and drinking chocolate, made for thousands of years in South America and Mexico from cocoa, can trigger the same neurochemical response as feelings of joy or love. Sounds like magic to me!

Making our deliciously decadent cocoa concoction requires unique partnerships between organic plants, carbon-rich soil, fair trade farmers, and responsible technology. Dr. Bronner’s Magic All-One Chocolate is made with the finest organic, fair trade, regeneratively grown cocoa and other wonderful plants, to produce an alchemy of seductive, energizing dark chocolate.

Other features:

- 70% cocoa—organic, fair trade, dynamic agroforestry-grown in Ghana and Ivory Coast.

- Made in Switzerland by an award-winning chocolatier.

- Indonesian organic, fair trade coconut sugar.

- Congolese organic, fair trade, dynamic agroforestry-grown cocoa butter.

- Organic, fair trade vanilla from Madagascar.

The Importance of Sustainably Grown High-Quality Cocoa

Cocoa is the main ingredient in chocolate. A major component of our mouthwatering chocolate is supporting the more than 800 fair trade cocoa farmers and partners we buy from. All the cocoa beans are coming from farmers we partner with at Serendipalm, our fair trade project in Ghana, and KANY, a co-op of women farmers on the Ivory Coast. Our cocoa farmers employ dynamic agroforestry (DAF) to regenerate the land.

Dynamic agroforestry—the integration of complementary trees and other profitable crops alongside the cocoa—creates biodiversity, offers farmers more security by improving yields and diversifying marketable products, and avoids the use of toxic chemicals by imitating the way plant species naturally support each other in a healthy tropical forest.

A dynamic agroforestry field showing cocoa, papaya, and other crops

Soil in this regenerative system is more resilient, contains more nutrients, holds water better, resists erosion, and mitigates global climate change by capturing more carbon.

And, our fair trade farmer partners are paid fair, sustainable, livable wages and prices for their regeneratively grown products that allows them to raise their children in thriving communities, with improved opportunities for education and medical care. We believe that our regenerative organic and fair trade model is addressing a lot of the historical social and environmental issues associated with old-school corporate cocoa production.

What Is the Cocoa Harvesting Process Like?

The very best chocolate requires cocoa to be carefully fermented and dried after harvesting at exactly the right time.

Harvesting: Pods containing cocoa beans grow from the trunk and branches of the cocoa tree. Harvesting involves removing ripe pods from the trees and opening them to extract the wet beans. The pods are harvested manually by making a clean cut through the stalk with a well-sharpened blade.

Fermentation: Fermentation can be carried out in a variety of ways, but all methods depend on removing the beans from the pods and piling them together (or in a box) to allow microorganisms to develop and initiate the fermentation of the pulp surrounding the beans. The piles are then covered with banana leaves to complete the fermentation process.

Cocoa beans being prepared for fermentation after being extracted from their pods

Drying Cocoa Beans: Cocoa beans are sun-dried after fermentation in order to reduce the moisture content from about 60% to about 7%. Drying must be carried out carefully and slowly to ensure that off-flavors are not developed. After the pulp has dissolved and the cocoa beans are fully dried, the beans are filled into bags and shipped off.

Using Coconut Sugar Instead of Cane Sugar

Sugar is used to balance the bitterness and flavor of cocoa. Our choice is to use organic, low-glycemic coconut blossom sugar. This decision is driven by coconut sugar’s environmental, social, and personal health benefits compared to cane sugar. Our partner, Aliet Green, an Indonesian woman-owned organic farm collective, produces a light and delicious coconut sugar that compliments the flavor of our West African cocoa.

Coconut sugar is made by extracting the sugary sap from coconut flower buds that have been harvested by farmers using traditional methods. The sap is then processed manually by evaporating the viscous nectar and reducing it down into sugar crystals.

Scrumptious Cocoa Butter and Vanilla

Organic cocoa butter from the fair trade Esco Kivu project in Eastern Congo is added to increase the smoothness, mouthfeel, and flowability in production of our chocolate.

Organic vanilla from Madagascar is used in small quantities to help create a flavor experience and journey that is cohesive and balanced.

What's the Process of Making the Chocolate?

Dr. Bronner’s has partnered with two top-ranked European chocolatiers to process our organic ingredients into magical chocolate.

First, the Swiss cocoa producer cleans, roasts, and grinds our cocoa beans. From there, the ground beans are transported to our Swiss chocolatier partner, where the chocolate is finished by mixing, rolling,and conching the cocoa, and molding all our organic ingredients into a delicious bar.

Upon arrival in Switzerland, the first step is to clean the beans and purify them using steam. Traditional roasting then occurs slowly and gently in small batches. Roasting times have been specified for our beans to obtain the flavor characteristics we desire. The cooled beans are then broken into smaller pieces by a breaking machine, and the shells removed. Finally, the broken beans are further refined into a powder by ceramic balls in a ball mill.

Mixing

Different amounts of cocoa butter, coconut sugar and other ingredients are added according to our special recipes. This takes place in a huge mixer. At this stage, the chocolate mass tastes close to the finished product .

Rolling (Fine Refining)

To refine the chocolate and remove all traces of gritty texture, the cocoa mass is rolled into a very thin sheet by several rollers. This chocolate sheet is thinner than a strand of human hair. The process is repeated several times until a very fine powder results.

Conching

At the conching stage, the powder from the refining step is transported to larger vessels called conches, where the chocolate mass is heated to around 80°C (176°F) and agitated (or stirred) continuously for several hours. This causes the bitter flavors to evaporate and allows the desired flavors to fully develop to our standard, creating a delicious liquid chocolate mass.

After this, inclusions or fillings are added to the chocolate mass and poured into molds.

And…voila! Dr. Bronner’s Magic All-One Chocolate is created for your uniquely satisfying, delectable, invigorating pleasure! All-One!